Description

High Quality Air: Proven high performance desiccant technology provides a pressure dew point of -40°C (-40°F) for critical applications; The pre-filter and post-filter protect the desiccant and downstream air from oil and particle contamination.

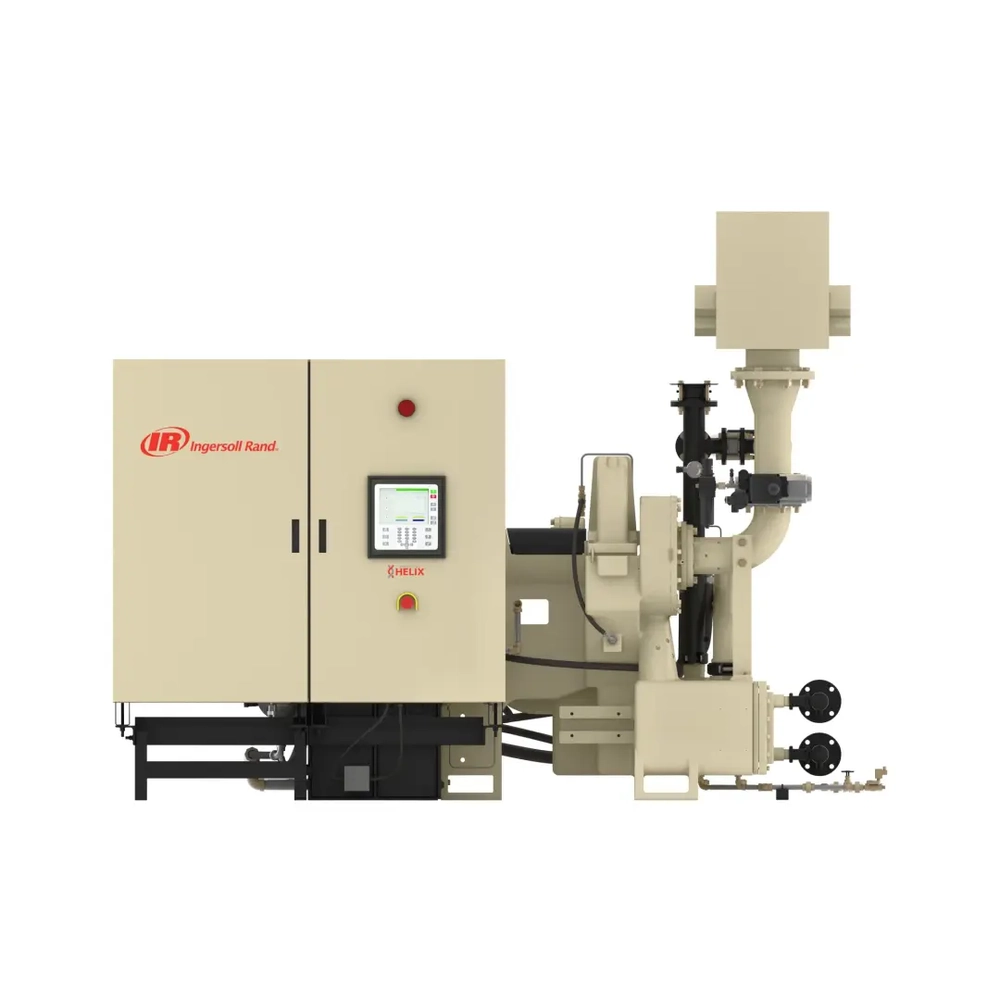

Easy to Maintain: A low-profile design and easy access to components simplify installation and maintenance.

Reliable Operation: Heavy-duty desiccant, along with durable valves and components, provides long service life.

Reduced Energy Consumption: Low pressure drop design saves on energy costs and offers an economical drying solution.

Smart Control with 7” display: Advanced, easy-to-use microprocessor helps maintain dryer performance at optimal levels by constantly monitoring functions and providing maintenance alerts as well as protection notifications.